Detachable door hinges are also a type of industrial hinge. We know that there are very many types of hinges used in industry. They are divided into different categories by different materials, structures, and functions. Today I want to share with you that this hinge is one of the more special ones.

I will discuss the following 8 aspects of detachable door hinges. If you are a buyer of hardware accessories for your company or a manufacturer of industrial equipment, then this kind of product knowledge is believed to be helpful to you. Let’s get down to business.

What are detachable door hinges?

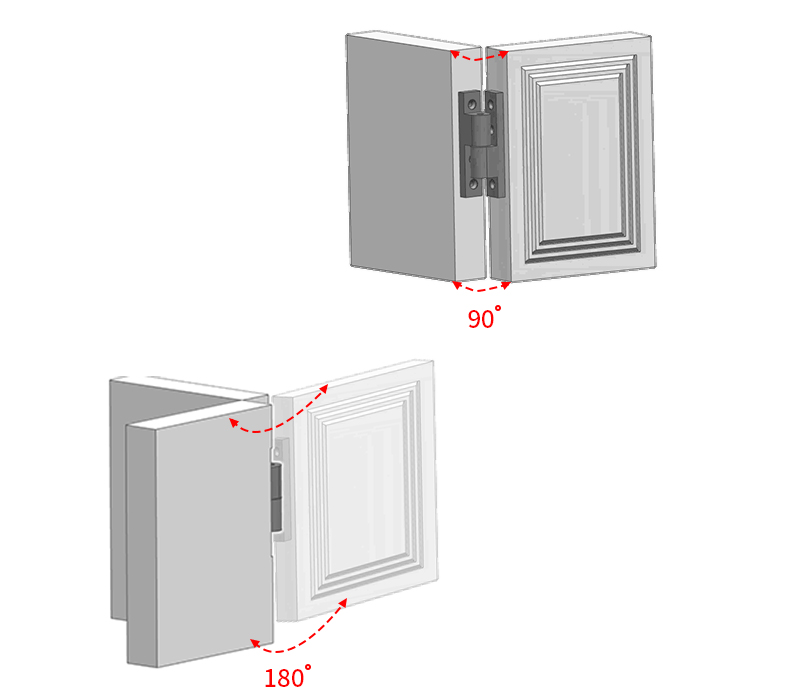

First, we need to get the concept clear. That is, what is a detachable door hinge? Literally, this hinge is a hinge that can be removed. Precisely, of course, after the hinge is installed on the door, we can remove the door at any time when needed. The key role in this is to remove the hinges.

Why do we need this type of hinge? Because in the field of industrial production, workers often need to deal with a variety of equipment. For example, industrial ovens, industrial test chambers, and environmental test chambers. There are also electrical boxes, electrical cabinets, etc. These devices basically have installed doors. But in the course of work, we often need to open the door for a long time. The best way to do this is to temporarily remove the entire door and install it after completing the work.

This may be the origin of the detachable door hinge.

What are the characteristics of detachable door hinges?

It has the obvious feature that it can be disassembled. Even so, the parts are separable from each other. For example, we have a class of concealed hinges in production. A significant number of them are of disassembled design. The hinge block and the core can be completely separated from each other. Although to some extent they are less load-bearing, this is sufficient to meet the requirements of the equipment.

Because of their removability, they are less load-bearing than some other heavy-duty industrial hinges. But it so happens that this type of hinge is also mostly used in lighter doors. For example, electrical cabinets, electrical boxes, etc. There is one special feature of heavy-duty detachable hinges that are generally custom-made. They need to be tailored to the customer’s actual product.

In addition, the service life of these hinges is relatively long. The hinges are not subject to the weight of the door because it is often necessary to remove the door. Although this is somewhat insignificant, the life expectancy is definitely better compared to some hinges that are subjected to the weight of the door for a long time. This is especially true for heavy-duty welded hinges. They are permanently mounted on the door and cannot be removed. They need to bear the weight of the door for a long time.

What materials are used to produce detachable door hinges?

Different load-bearing and use environments determine what materials are used to produce detachable door hinges. We know that these hinges are generally not very load-bearing, so the requirements for materials are not high. Commonly used materials are cold rolled sheets, aluminum, zinc alloy, or stainless steel.

The cold rolled sheet is the most used material and is often used to produce those detachable hinges used on electrical cabinets and boxes. The requirements for hinges on these box devices are not high, as long as they achieve functionality. For small box doors like these, the requirements for the hinge’s connection function are greater than the requirements for the hinge’s load-bearing performance. That is to say, basically, metal hinges can meet the weight-bearing requirements of this type of box equipment.

Then there is the stainless steel material, some hinges are used outdoors. In order to avoid maintenance, the use of stainless steel is the most cost-effective choice. Because this type of material has good anti-corrosion properties and self-healing function. The general harsh environment can not make them corrode or rust.

But no matter which material, the production process of the hinge is also very important. The hinges mentioned above are produced using stamping dies, while another process is die-casting. This process is often used to produce detachable door hinges with greater performance.

For example, we produce zinc alloy detachable hinges for our customers, as well as stainless steel die-cast detachable hinges. These hinges are special custom-made hinges with high load-bearing performance. But they are also designed to be removable, which is determined by the actual usage requirements. For IHINGES, we need to ensure both the removability of these hinges and their strong load-bearing properties. This will ensure that the door works properly in the long term.

What are the uses of detachable door hinges?

There are two main uses for this type of removable hinge. On the one hand, it is used on the design doors of lighter electrical boxes, electrical cabinets, network cabinets, server racks, etc. This is also the most used scenario. On the other hand, is a special type of removable hinges that are custom-made for customers. These hinges are basically customized for each actual product or equipment. Some of them have a flat mounting structure and some have a step mounting structure.

The load-bearing capacity of these hinges is much greater than that of the previous type. And they are all produced using the die-casting process. This production process allows for thicker, heavier hinges to be produced. They are able to withstand the strong gravity of the door while satisfying the demolition function.

How to install Removable hinges?

Proper installation of hinges is an important factor for a door to work properly. Here is a basic step-by-step guide on how to install a detachable door hinge.

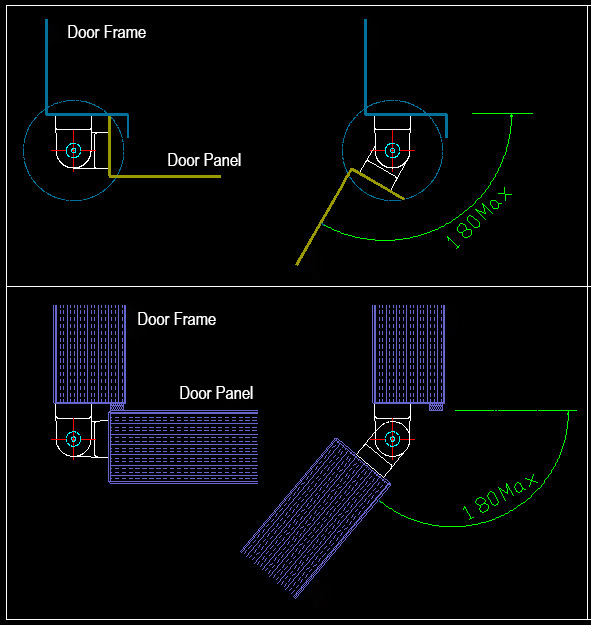

First, we need to select the hinges to be installed and the number of hinges to be installed. Before installation, place the hinge on the door or door frame and mark it with a pen for easy installation by opening the hole or welding. Pay attention to the position of the hinges here, and make sure to have the exact dimensions. After that, install one side of the hinge on the door frame first, and then install the other side of the hinge on the door. After both are installed, then just connect the door to the door frame by the hinge spindle.

Finally, check that the door can be opened and closed correctly.

How to choose a suitable detachable hinge?

If your equipment is a small, light box equipment, then you can use the stamping molding detachable hinge. The material can be iron or stainless steel, depending on the actual use of the environment to determine. If your equipment is heavy-duty, it is recommended to use die-casting hinges. I have already mentioned the reasons above, so I will not repeat them here.

Here is an article dedicated to how to choose a detachable industrial hinge.

How to order a detachable hinge?

HINGES is a professional manufacturer of custom-made industrial hinges. Detachable door hinges are one of the products we focus on developing and producing. We specialize in making heavy-duty detachable hinges for our customers. If you are looking for this type of hinge, then you have come to the right place. Please feel free to contact us and we will get back to you quickly after understanding your requirements.