Industrial machinery operates under extreme conditions, requiring robust and reliable components to ensure optimal performance. Among these components, industrial piano hinges play a vital role in providing seamless functionality to heavy-duty machinery. This blog post explores the significance of industrial piano hinges, delving into their features, applications, and benefits for the industrial sector.

Understanding Industrial Piano Hinges

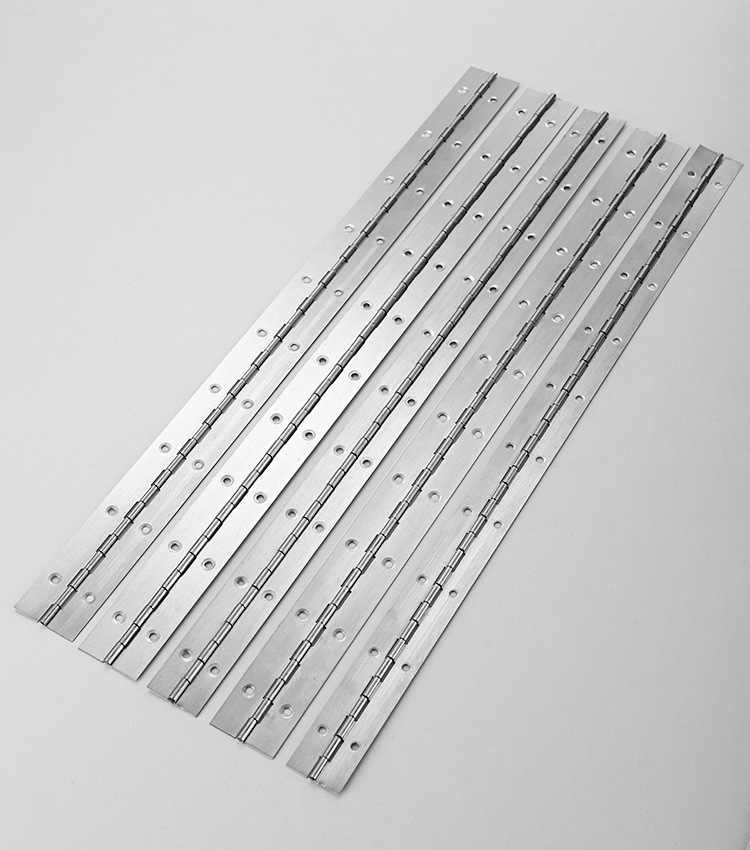

Industrial piano hinges are engineered to facilitate smooth movement and provide long-lasting performance in demanding environments. These hinges consist of two continuous plates interconnected by a central pivot pin, enabling rotation and weight distribution. By understanding their purpose and key characteristics, businesses can harness the power of industrial piano hinges for enhanced machinery functionality.

Types of Industrial Piano Hinges

- Continuous hinges: Designed for applications that require long, uninterrupted lengths, continuous hinges offer exceptional strength and durability. They find utility in heavy-duty machineries, such as manufacturing equipment and large-scale access panels.

- Butt hinges: Well-suited for heavy-duty machinery doors and panels, butt hinges provide reliable support and smooth operation. Their robust construction ensures stability and longevity, even in high-stress conditions.

- Heavy-duty strap hinges: Often used in heavy machinery, strap hinges offer substantial load-bearing capacity, making them ideal for supporting large and heavy components. Their versatility allows for application in various industrial sectors.

- Industrial pivot hinges: Engineered to enable smooth rotation for machinery parts, pivot hinges are crucial in applications such as conveyor systems, automated assembly lines, and adjustable machinery components. Their precision and stability contribute to the seamless operation of heavy-duty machinery.

Strength and Durability

Industrial piano hinges are manufactured using high-quality materials to withstand heavy loads, constant movement, and harsh conditions. Commonly employed materials include stainless steel, carbon steel, and reinforced alloys. The durability of these hinges ensures consistent performance, reducing maintenance and replacement costs for businesses.

To meet industry standards, industrial piano hinges undergo rigorous testing procedures. Various certifications, such as ISO and ASTM, ensure compliance with quality and safety requirements. These testing standards provide assurance of the hinges’ strength, load capacity, and corrosion resistance, guaranteeing their reliability in heavy-duty machinery applications.

Applications of Industrial Piano Hinges

- Heavy machinery manufacturing: Industrial piano hinges secure access panels and doors in heavy machinery, enabling easy maintenance, inspection, and component replacement. Their robust construction ensures the integrity of machinery enclosures, providing a safe working environment.

- Industrial equipment cabinets: Hinges play a crucial role in enhancing stability and functionality in equipment cabinets, ensuring smooth opening and closing movements. They enable efficient access to machinery controls and components, optimizing operational efficiency.

- Transportation industry: Piano hinges find extensive use in securing doors, hatches, and compartments in transportation vehicles such as trucks, trains, and ships. Their reliability ensures the safe transport of goods and passengers by providing secure and reliable closures.

- Aerospace and defense: The aerospace and defense sectors rely on industrial piano hinges for their critical systems, including aircraft access panels, missile launchers, and military vehicle components. These hinges contribute to the precision and security required in these applications.

Installation and Maintenance Considerations

Proper installation techniques are essential to ensure the optimal performance of piano hinges. This includes accurate alignment, appropriate fastening, and adherence to manufacturer guidelines. Regular maintenance, such as lubrication and inspection, is crucial to prevent wear and ensure the longevity of the hinges. Prompt identification and resolution of common issues, such as misalignment or corrosion, can prevent costly disruptions in machinery operation.

Safety and Security Features

Thes hinges incorporate safety and security features to protect machinery and prevent unauthorized access. Anti-tamper mechanisms, such as concealed screws or special fasteners, enhance security by deterring tampering or sabotage attempts. Locking options, such as integrated locks or

special fasteners, enhance security by deterring tampering or sabotage attempts. Locking options, such as integrated locks or padlock compatibility, provide an extra layer of protection for sensitive machinery and equipment. Compliance with safety regulations and industry standards ensures the implementation of best practices for maintaining a safe working environment.

Customization and Specialized Solutions

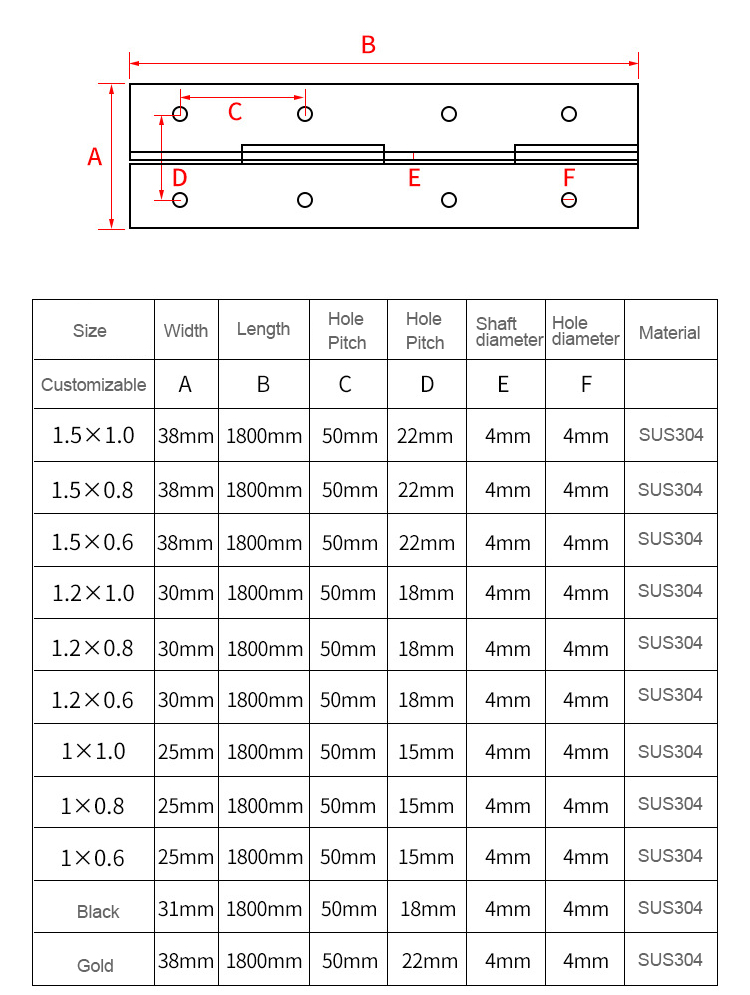

Manufacturers of industrial piano hinges offer customization options to cater to unique machinery requirements. Collaborating with these manufacturers allows businesses to design bespoke hinge solutions tailored to their specific needs. Customization may include materials, dimensions, load capacities, or special features, enabling businesses to optimize machinery performance and efficiency.

Industry Case Studies

Real-world examples highlight the benefits of industrial piano hinges in diverse industrial applications. Case studies showcase successful implementations, demonstrating the impact of these hinges on machinery performance, productivity, and safety. Testimonials from satisfied customers further validate the value and reliability of piano hinges in their respective industries.

Future Trends and Innovations

Advancements in piano hinges technology continue to shape the heavy machinery industry. Innovations aim to improve load-bearing capacities, reduce friction, enhance corrosion resistance, and incorporate smart features for monitoring and maintenance. Emerging trends, such as the integration of IoT (Internet of Things) sensors or lightweight materials, hold the potential to revolutionize the functionality and efficiency of heavy-duty machinery.

Conclusion

Industrial piano hinges play a crucial role in ensuring the seamless operation of heavy-duty machinery in various industrial sectors. Their strength, durability, and reliability contribute to enhanced functionality, safety, and productivity. By understanding the types, applications, installation, and maintenance considerations, businesses can harness the benefits of industrial piano hinges for their specific machinery requirements. As the heavy machinery industry evolves, staying abreast of future trends and innovations will enable businesses to leverage the latest advancements in hinge technology for continued success.