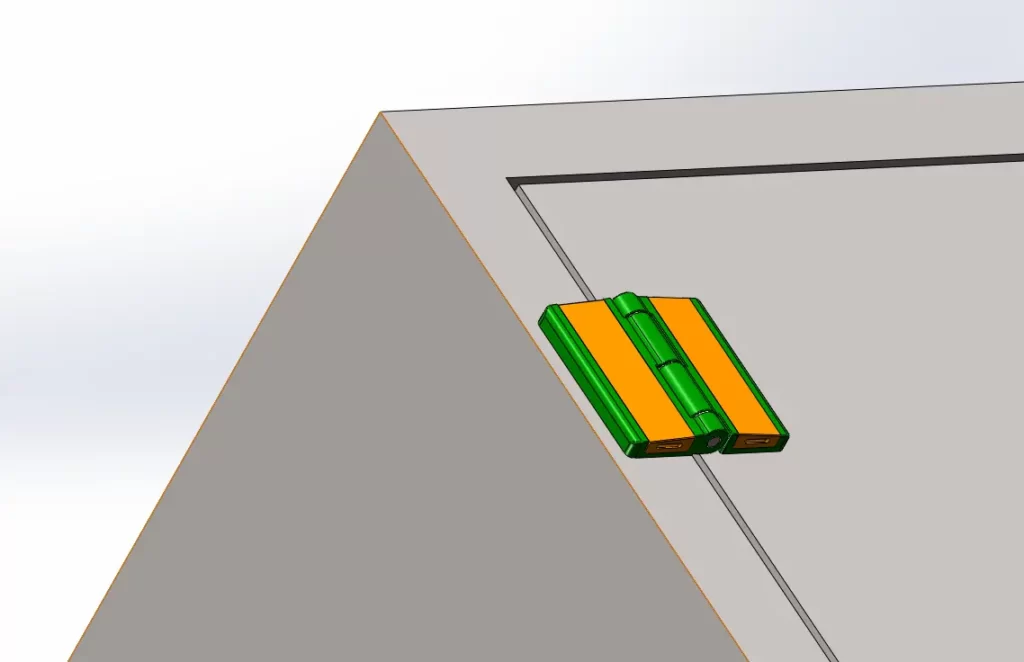

Among the accessories for industrial ovens and other test equipment, hinges are one of the important ones. We call them heavy-duty oven hinges. Almost all industrial test equipment is equipped with doors, which inevitably requires the use of complementary hinge products and industrial handles and other accessories.

As a professional manufacturer of industrial hinges, these products are naturally the focus of IHINGES. In today’s article, I will focus on hinges for industrial inspection equipment from a design perspective. If you are a hinge buyer or a manufacturer of industrial inspection equipment, it may be helpful for you to have the opportunity to purchase industrial hinges.

What are the heavy-duty oven hinges designed for?

Industrial ovens are just one type of testing equipment among industrial test equipment. Different testing equipment has different functions and different requirements for various accessories. So we need to be clear at the beginning of the hinge design what is its purpose?

Specifically, what are the requirements of the box door? Does it need to be sealed, insulated, thermal insulation, or all three? If it needs to be sealed, what are the requirements for the hinge? Or what are the requirements for the hinges if they need to be insulated and moisturized? At the very least, the design engineer needs to understand this question.

In general, the requirements of industrial testing equipment for the door are mainly sealing, insulation and moisture. And these requirements can basically be met. Moreover, heat preservation and water retention especially need the door seal to play a role.

The environment in which heavy-duty oven hinges are used

Heavy-duty oven hinges are used in environments that are mainly inside factories. Rarely is it used outdoors? So relatively speaking, these hinges are used in a good environment. Knowing this situation especially helps the designer to decide on the material of the hinge.

Even though the conditions inside different testing equipment are different, some equipment is in a high-temperature condition inside, some are in a high humidity condition inside, and there is also equipment that vibrates strongly during operation. All of these can hinge on design considerations.

For example, if the equipment generates vibrations, there are certain requirements for the hinge installation. It may be necessary to add cushioning pads to prevent the loosening of the equipment hinges during extended use.

What is the customer’s budget?

The customer’s budget is a factor other than the product. But it is very important, after all, any product has a cost. Considering the cost and helping customers to save as much as possible while meeting their needs is itself a key consideration for us. This is an important part of creating value for our customers. A product design that doesn’t take cost into account is not a good product design. Nor is it a good designer.

There are many factors that affect the cost, including material, function, structure, and production process. Heavy-duty oven hinges are mainly made of zinc alloy and stainless steel. We can use the cheaper zinc alloy material to design products for our customers if we can meet their needs. After all, these products are mainly used indoors and will not be affected by the harsh outdoor environment.

In addition, the structure design is also very important. A clever structural design can turn complexity into simplicity. It not only saves materials but also brings great convenience to subsequent production. Therefore, it is the basic quality of a mature designer to stand in the customer’s perspective and help him save his budget.

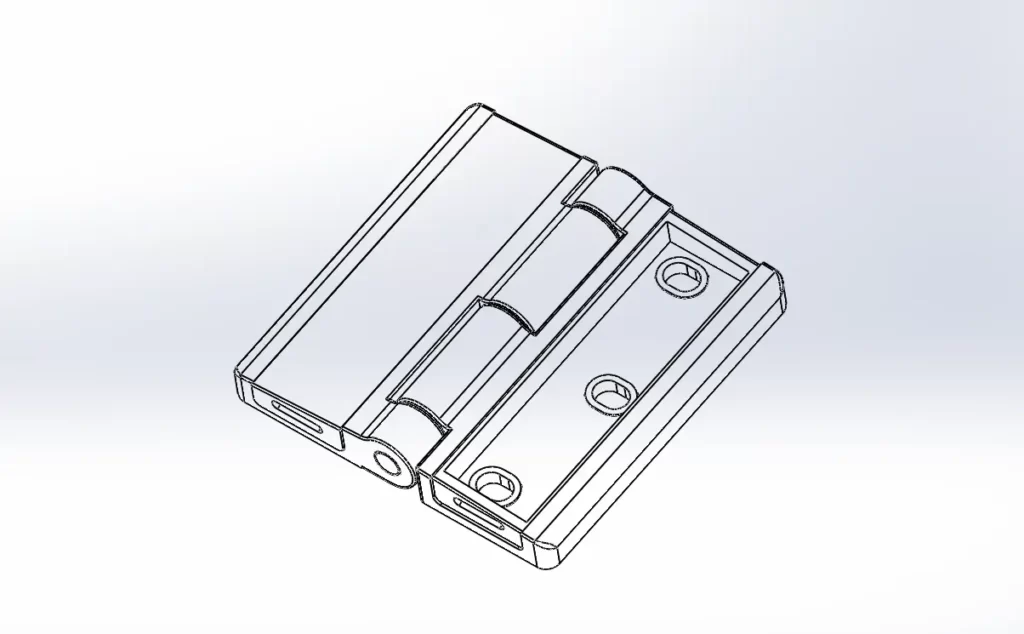

How is the structure of a hinge designed?

The structural design of heavy-duty oven hinges is one area where the merit of the hinge designer is considered. Once we understand the customer’s needs, we will have a variety of design options, an important one being structural design. Different structural designs are available to meet the customer’s needs, but is it the simplest, most convenient, and most cost-effective structure? This requires a lot of thought.

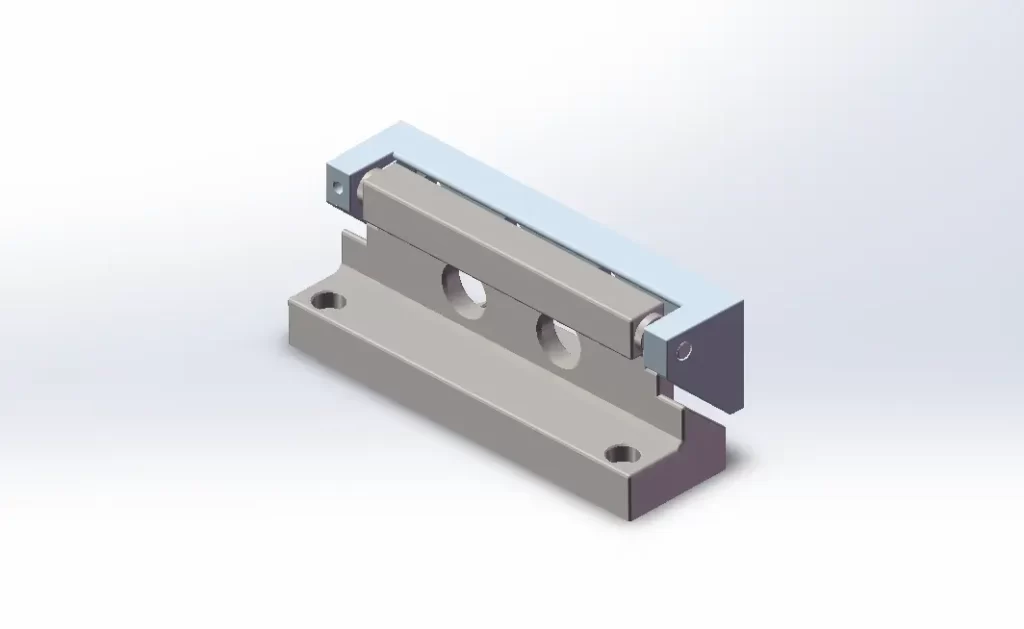

The structure of hinges for testing equipment is generally similar. Because the hinge itself is a simple structure of products, the most basic is two hinge blocks and a hinge core. However, there are some details that can be considered in depth.

What materials are used for production?

The choice of material is an important factor. This is decided at the beginning of the hinge design because of this issue. If the customer does not specifically want it, we will determine whether it should be made of zinc alloy or stainless steel based on factors such as the important size of the testing equipment door and the frequency of use.

If the customer specifies a more robust material, then we recommend stainless steel. In general, however, whether made of zinc alloy or stainless steel, they are produced using die-casting and casting processes. This will meet the requirements of the door of the testing equipment because the door of this type of equipment is generally thicker and heavier. If the ordinary butt hinges with stamping molding, it will look too thin.

Surface Finishes

Which finish to use depends on the material of the hinge. Generally, zinc alloy material can be done with various finishes. For example, electroplating, electrophoresis, painting, oxidation, etc. Different colors can also be chosen. Especially when the appearance of the hinge needs to match the arrival of the testing equipment, the use of the specified color can make the overall equipment look very beautiful and simple.

Using stainless steel, its surface treatment is generally polished. It can be brushed polished or mirror polished. It has good anti-corrosion properties and does not require a protective layer on the surface.

What is the design life of heavy-duty oven hinges?

The design life of the heavy-duty hinges is also an important factor. Some testing equipment is used less frequently, and the corresponding life expectancy requirement can be lower. Some are used very frequently, and then the service life needs to be considered in a focused manner.

Can be simply calculated. For example, the equipment door to open and close 50 times a day, and the service life of the equipment if it is 10 years. Then the number of times the hinge opens and closes needs to reach nearly 200,000 times the requirement. This requires a specific test fixture to test.

How much hinge load is designed?

Then there is the design of the hinge load-bearing. The initial estimate of the hinge load size is based on the importance of the testing equipment door. Usually, we will simply calculate the load-bearing size of a single hinge. For example, if the door weight is 120 kg, then when two hinges are installed, the load capacity of a single heavy oven hinge is 60 kg. if three hinges are installed, then the load capacity of a single hinge is 40KG. in fact, this is not a rigorous method.

The strict calculation, if a door is important is 120KG, then the requirement of each hinge individual load should also be 120KG.

How hinges move

A hinge’s trajectory needs to be considered during structural design. Of course, we know that the trajectory of a hinge is a rotation of one of the hinge blocks around the other hinge block. The axis of rotation is the hinge axis. However, the size of the opening angle needs to be considered in terms of the actual requirements.

Some equipment needs to be opened at an angle of fewer than 90 degrees, and some equipment doors need to be turned completely over so that the contents of the box can be removed.

Whether to focus on appearance design

The appearance factor is the last to be introduced. But it is indeed the most likely to attract the attention of customers. Because the first thing customers look at is the appearance of the hinge. A heavy-duty oven hinge with a beautiful, simple design is often more likely to attract the attention of customers.

When it is understood that the features are up to snuff, the customer is more likely to choose a cooler, more beautiful, and simpler hinge.

If you are currently looking for a custom industrial hinge manufacturer, then you have come to the right place. You can fill in your email and product requirements in the form below and we will get back to you as soon as possible. Contact us now.