Industrial manufacturing is a space riddled with innovation and niche components, each tailored to specific needs. Among these components, one might wonder, what are duck hinges? More importantly, what are they used for in this sector?

Duck hinges, predominantly found in the industrial manufacturing sector, are specialized hinges that offer precise movement and positioning capabilities. They play a significant role in ensuring smooth operations, particularly where precision and durability are paramount.

In the next few sections, we’ll delve deeper into the various applications and facets of these intriguing components. Strap in, because it’s going to be an enlightening journey!

Why is precision so important in industrial manufacturing?

Precision is the backbone of many industrial operations. Without it, products might falter, and operations could grind to a halt. In scenarios demanding meticulous attention to detail, components like duck hinges come to the forefront, bridging the gap between precision and functionality.

How do duck hinges contribute to machine safety?

Safety is paramount in industrial settings. Machines, often colossal in size, can be dangerous if their parts don’t function seamlessly. These hinges ensure a certain predictability in movement. This predictability, combined with their robustness, minimizes unexpected machine behaviors, significantly enhancing overall safety.

Why are duck hinges preferred for repetitive operations?

Consistency is a key aspect of manufacturing. When machines perform repetitive tasks, it’s crucial that their movements are uniform each time. Enter the hinges. With their unique design and superior materials, they offer consistent movement, minimizing wear and tear even in repetitive scenarios, ensuring longevity and reliability.

How do these hinges affect product quality?

In industrial manufacturing, even minute inconsistencies can spell disaster for product quality. Duck hinges, with their precise positioning capabilities, ensure that machinery operates with utmost accuracy. This, in turn, reflects on the end product, guaranteeing top-notch quality every single time.

Are duck hinges a sustainable choice?

Sustainability is the buzzword of our times. Even in manufacturing, choosing components that last longer translates to less waste and reduced resource consumption. Thanks to their design and the materials used, the hinges are incredibly durable. Their longevity means fewer replacements, aligning with the sustainability goals many industries now pursue.

How do duck hinges influence machine maintenance?

Maintenance can be a significant overhead in the manufacturing sector. The easier it is to maintain a machine, the more cost-effective its operation becomes. By utilizing the hinges, machines experience less wear and tear. This translates to fewer maintenance intervals and less downtime, saving both time and money in the long run.

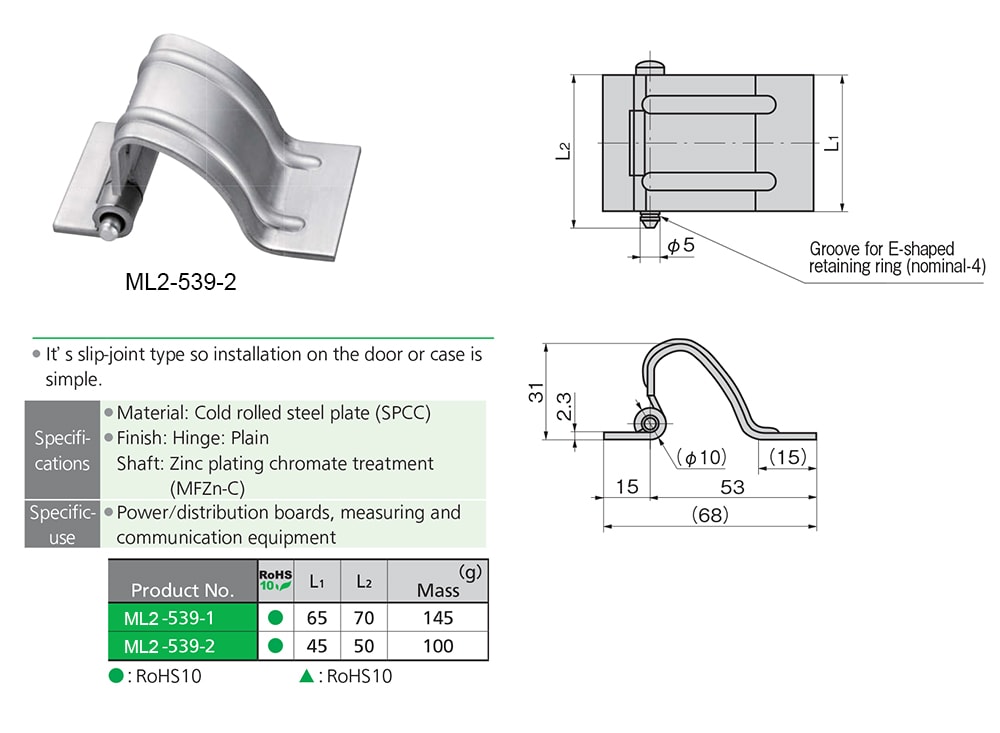

Can duck hinges be customized for specific manufacturing needs?

Every manufacturing process is unique. Sometimes, off-the-shelf components just don’t cut it. Fortunately, the hinges are versatile. Many manufacturers offer customization options to ensure these hinges fit seamlessly into any machine design, catering to a plethora of industrial requirements.

How do duck hinges stack up against traditional hinges?

Traditional hinges have their place, but in high-demand industrial scenarios, can they truly compare to these hinges? From what we’ve explored, duck hinges offer superior precision, durability, and consistency. While traditional hinges might suffice in less demanding environments, when it comes to rigorous industrial applications, the hinges undoubtedly take the crown.

Conclusion

To sum it up, duck hinges are more than just a component in the manufacturing sector. They’re a testament to how the right piece, tailored for precision and durability, can drastically influence operations. From ensuring safety and product quality to reducing maintenance costs and supporting sustainability, the hinges truly are unsung heroes in the vast expanse of industrial manufacturing.

You might also be interested: