Gates, especially those used for industrial or commercial purposes, serve as more than just entrance and exit points; they’re symbols of security, efficiency, and design prowess. The right hinge ensures optimal performance and prolonged gate life, and for heavy-duty gates, this becomes even more paramount.

When considering the best hinges for heavy-duty gates, one must evaluate aspects like material, bearing capacity, corrosion resistance, and overall design. Only then can you ensure that the hinge will stand up to the demands of heavy traffic and environmental factors.

With this knowledge in hand, let’s delve into the various hinge options available for heavy-duty gates, weighing their pros and cons.

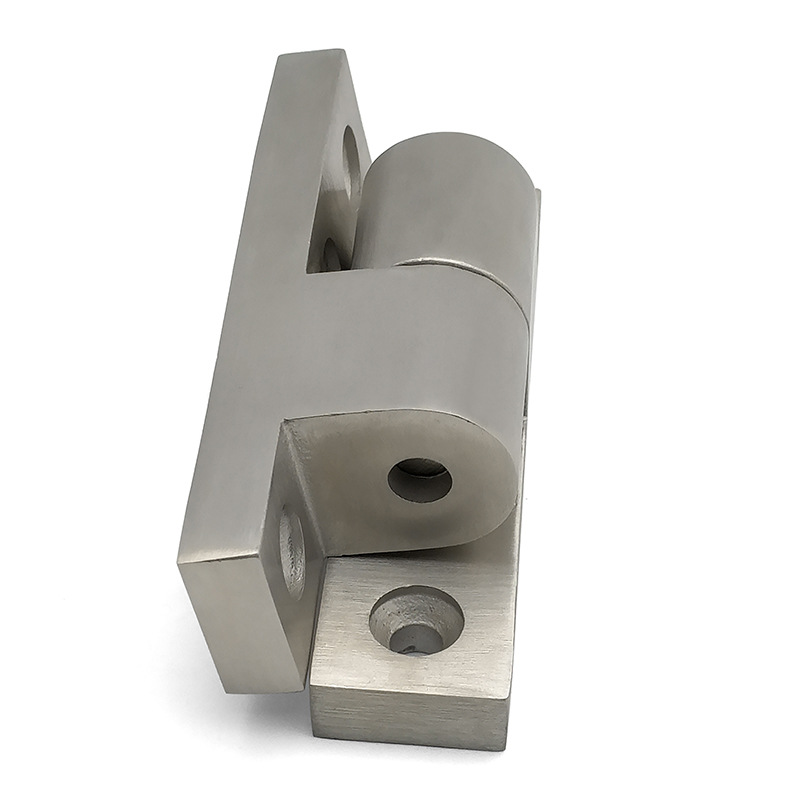

What are Barrel Hinges and How do They Fit Heavy Duty Applications?

Barrel hinges, often cylindrical in shape, offer a seamless design that hides the hinge’s pivot point. This not only offers a clean look but also enhances security.

For heavy-duty gates, especially those used in industrial applications, barrel hinges made of hardened steel or stainless steel can provide the necessary strength. Their design ensures even weight distribution, preventing sagging or misalignment. However, one must ensure regular maintenance, as these hinges can be susceptible to dirt and debris accumulation.

Why Should One Consider Pivot Hinges for Heavy Duty Gates?

Pivot hinges, unlike traditional side hinges, are mounted at the top and bottom of the gate. This unique positioning can be beneficial for heavy-duty gates.

Given their design, pivot hinges distribute the gate’s weight more evenly across its height. This minimizes stress on any one point, making them ideal for tall or heavy gates. Materials like stainless steel or brass enhance their durability, but one must ensure that the surrounding structure can support the hinge’s mounting requirements.

How do Butt Hinges Benefit Heavy Duty Applications?

Butt hinges are perhaps the most common hinge type. Comprising two rectangular plates (leaves), they are simple yet effective.

When forged from materials like steel or brass and combined with high-strength pins, butt hinges can support considerable weight. Their simplistic design also facilitates easier maintenance and replacement. However, for extremely heavy gates, it’s vital to use multiple butt hinges to distribute weight and prevent undue stress.

Are Continuous (Piano) Hinges Suitable for Heavy Duty Gates?

Continuous hinges, spanning the full height of a gate, offer unparalleled weight distribution. Named after their use in piano lids, do they find relevance in heavy-duty applications?

Indeed, for gates that need uniform support across their length, continuous hinges provide an optimal solution. When crafted from stainless steel or aluminum, they promise durability and rust resistance. The continuous design also prevents any gate sagging. However, their installation might be more time-consuming compared to other hinge types.

Why Are Strap Hinges a Common Choice for Heavy Duty Gates?

Strap hinges, characterized by their long and decorative leaves, combine both aesthetics and functionality.

For heavy-duty gates, particularly in farms or rural settings, strap hinges offer a rustic appeal without compromising strength. When made of galvanized steel or iron, they resist environmental wear and tear. Their length assists in weight distribution, but they require robust mounting points to ensure longevity.

How do T-Hinges Compare for Heavy Duty Applications?

T-hinges, named due to their shape, present both a vertical and horizontal plate, optimizing support.

Given their design, T-hinges offer substantial support to heavy-duty gates, especially when made from materials like steel or iron. Their unique shape ensures even weight distribution, minimizing gate sagging. However, for optimal performance, regular maintenance to prevent rust or corrosion is essential.

Do Weld-on Hinges Offer Benefits for Heavy Duty Gates?

Weld-on hinges, as the name suggests, are directly welded onto the gate and its supporting structure. This offers a secure and permanent hinge solution, but is it apt for heavy-duty scenarios?

Absolutely. Weld-on hinges, particularly those crafted from steel or heavy-duty alloys, provide unparalleled strength. The welding ensures minimal movement, reducing wear and tear. They are particularly suited for environments where hinge tampering might be a concern. The only caveat is the need for professional installation.

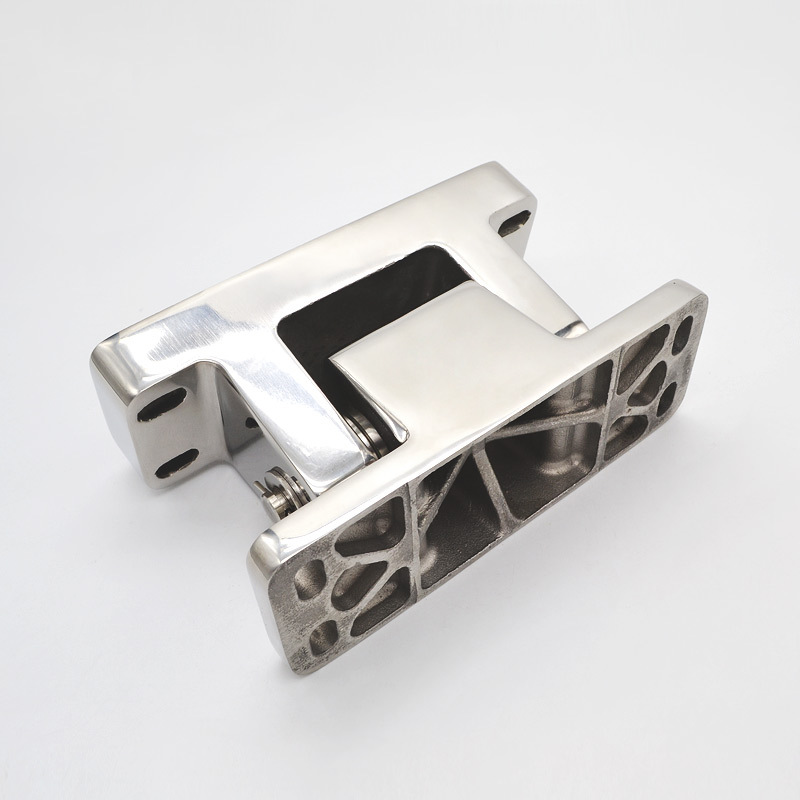

Are Gate Spring Hinges Effective for Heavy Duty Gates?

Gate spring hinges incorporate a spring mechanism that automatically closes the gate after it’s opened. This self-closing feature is advantageous, but does it align with heavy-duty needs?

For security-intensive areas, spring hinges ensure the gate remains closed, adding an additional layer of safety. When manufactured from stainless steel or brass, they can support considerable weight. However, regular checks to ensure the spring mechanism remains intact is crucial.

Conclusion

In selecting the right hinge for heavy-duty gates, understanding the gate’s specific requirements, and the hinge’s characteristics is crucial. Whether it’s the weight-distributing prowess of pivot hinges or the security offered by weld-on hinges, making an informed choice can elongate your gate’s lifespan and ensure optimal functionality.

For those looking to integrate premium hinge solutions, our expertise is unparalleled. As leading industrial hinge manufacturers, we marry quality with affordability. We specialize in crafting customized hinges, perfectly tailored to fit your equipment installation. Seek a competitively priced quote from us today.

You might also be interested: