Understanding the difference between standard and heavy weight hinges is vital in the industrial manufacturing sector. This knowledge guides professionals in selecting the right hinge type for various applications. Knowing which hinge to use ensures that doors, machinery, and other fixtures operate smoothly and safely.

Standard hinges are commonly used for lightweight doors or panels, offering flexibility and efficiency, while heavy weight hinges are designed to handle more weight and stress, typically used in industrial settings where strength and durability are paramount. Selecting the wrong type could lead to inefficiency and potential failure.

The decision between these two hinge types must be made with careful consideration of factors like weight, usage, and environment. Below, we will explore the detailed characteristics, applications, and considerations for both standard and heavy weight hinges.

Definition of Standard Hinges

What are Standard Hinges?

Standard hinges are those typically used in applications that do not require substantial support. They are designed for residential or light commercial use. Made from lighter materials and with a simpler construction, standard hinges are suited for everyday applications where heavy-duty support is not necessary.

Applications of Standard Hinges

Standard hinges are best suited for interior doors, cabinets, and other lightweight applications where heavy-duty support is not needed. Their flexible design makes them suitable for various non-industrial uses, from home furniture to office cabinets, where cost-effectiveness and aesthetics may be prioritized.

Definition of Heavy Weight Hinges

What are Heavy Weight Hinges?

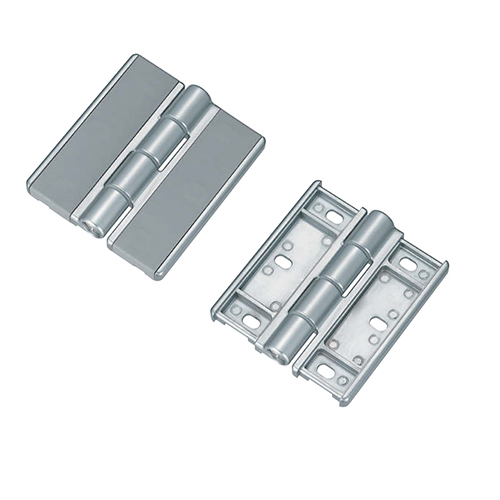

They are crafted with thicker material and a more robust design to bear substantial weight. They are specifically designed for industrial settings where strength is required. With a focus on durability and resilience, they are manufactured to withstand challenging environments.

Applications of Heavy Weight Hinges

They are commonly used in heavy doors, gates, and industrial equipment where higher levels of support and durability are needed. Whether it’s heavy machinery doors or security gates, these hinges provide the essential robustness and stability required in industrial contexts.

Comparison Between Standard and Heavy Weight Hinges

Material and Construction

Standard hinges are usually made of thinner material, while these hinges use more robust and denser material to handle more weight. Standard hinges may consist of materials like brass or light steel, while heavy weight hinges could be made of stainless steel or wrought iron.

Durability and Strength

Heavy weight hinges offer superior durability and strength compared to standard hinges. Designed with reinforced structures and often treated for corrosion resistance, they are built for long-term use in demanding environments. Standard hinges, although practical for light usage, may wear out more quickly under intense stress.

Cost

Standard hinges are typically more affordable due to their simpler design and lighter material. They are often chosen for budget-conscious projects where heavy-duty performance is not required. The hinges, with their robust construction and quality materials, are an investment that reflects their durability and performance.

Customization

Both types of hinges can be customized, but heavy weight hinges often require more precise engineering. Standard hinges offer more aesthetic customization, while the hinges need specific designs to meet particular industrial needs. Collaboration with designers and a well-equipped factory is essential for customization.

Which to Choose: Standard or Heavy Weight?

Considerations for Choosing

When selecting between standard and heavy weight hinges, consider factors like application, required strength, budget, and customization needs. Understanding the weight and frequency of use can help determine the suitable hinge type. Additionally, environmental factors like weather and humidity might also influence the choice.

Recommendations for Different Scenarios

For lightweight applications, standard hinges are usually adequate. For heavy industrial use, opt for the hinges to ensure optimal performance and durability. Specialized knowledge of industrial hardware accessories can help make a tailored choice that fits specific scenarios and adheres to necessary safety and quality standards.

Conclusion

Understanding the difference between standard and heavy weight hinges is vital for selecting the right hardware for your needs. Standard hinges are suitable for lightweight applications, while these hinges offer strength and durability for industrial uses. Selecting the right type contributes to efficiency, safety, and overall satisfaction in both manufacturing and utilization. Always consider factors like application, material, cost, and customization to make an informed and effective decision.

You might also be interested: