When it comes to ensuring the longevity and functionality of machines, especially those with doors, choosing the right hinges is crucial.

These small components play a significant role in the daily operation, security, and maintenance of machinery. Selecting the appropriate machine door hinges requires understanding their durability, corrosion resistance, safety features, and more to ensure they meet your specific needs.

Knowing what to look for can save time, money, and prevent operational downtime. Let’s dive into the top 10 important aspects to consider before making your hinge selection.

Durability and Load Capacity

Durability and load capacity are paramount when selecting machine door hinges. These hinges must withstand frequent use and bear the weight of the door without sagging or breaking. The materials used, such as stainless steel or brass, and the design of the hinge, including its thickness and the type of bearings, contribute to its strength and lifespan.

Understanding the environment in which the machine operates is also essential. Hinges used in heavy-duty applications should be robust and designed to handle higher loads. Consider the maximum weight the hinges need to support and ensure they have a safety margin beyond the door’s weight to accommodate any additional stress. Often these hinges are referred to as heavy duty hinges.

Corrosion and Rust Resistance

In environments where moisture, chemicals, or extreme conditions are prevalent, choosing hinges that resist corrosion and rust is crucial. Stainless steel and coated materials offer superior resistance and ensure the longevity of the hinges. This is particularly important in industries such as food processing, marine, and chemical manufacturing, where exposure to harsh conditions is common.

Selecting hinges with a finish appropriate for your environment not only extends their life but also maintains their appearance and functionality. Whether it’s a galvanized, powder-coated, or stainless steel finish, the right choice will prevent deterioration and maintenance issues.

Safety Features and Locking Mechanisms

For machines that require secured access or have safety concerns, hinges with integrated safety features and locking mechanisms are essential. These features prevent unauthorized access and ensure the door remains closed or locked in position as needed. From self-closing hinges to those with built-in locks or padlock eyes, the options vary depending on the level of security required.

Consider the type of lock mechanism that best suits your needs, whether it’s for child safety, theft prevention, or to comply with industry regulations. The right hinge can provide peace of mind and add an extra layer of security to your machinery.

Ease of Installation and Adjustability

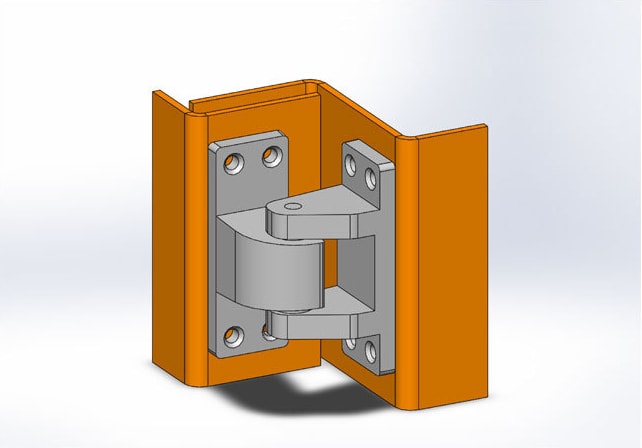

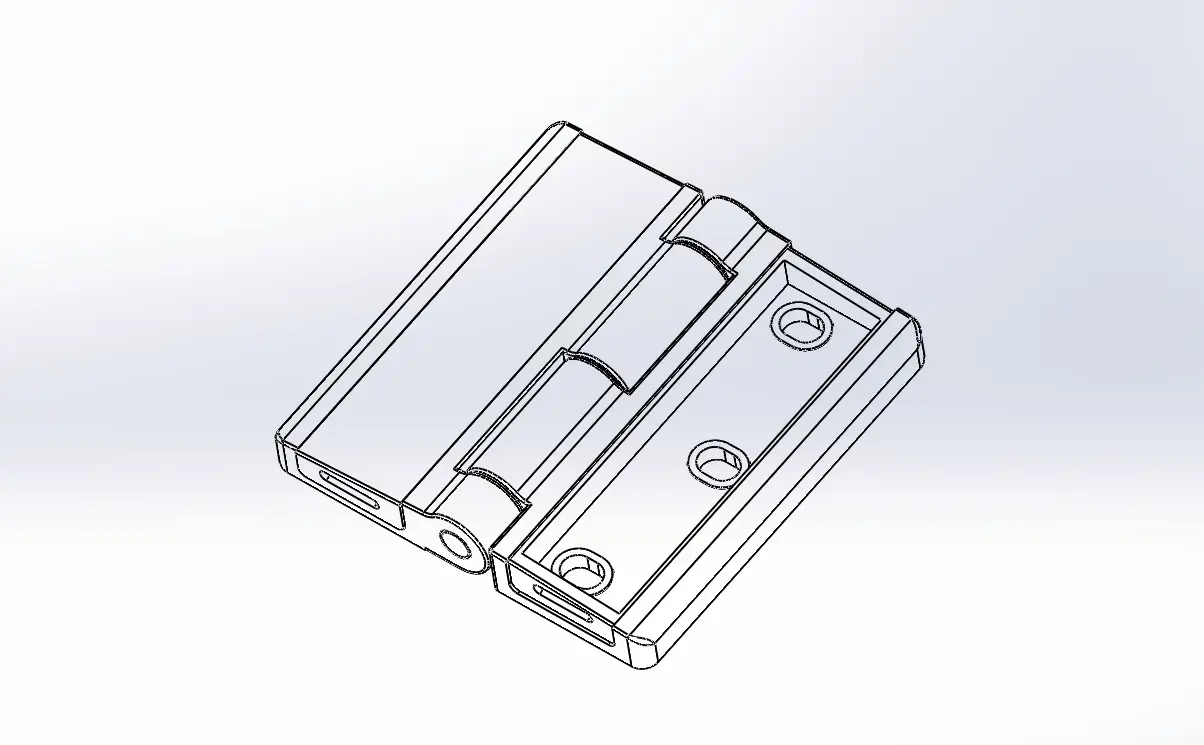

Ease of installation and adjustability are key factors to consider, especially when dealing with complex machinery or tight spaces. Hinges that are easy to install and adjust can save significant time and effort during the setup or maintenance phases. Look for hinges with adjustable features such as slotting holes or adjustable brackets that allow for fine-tuning the door alignment after installation.

For example, this industrial oven hinge features long round holes that can be fine-tuned during installation. This flexibility is crucial for ensuring a perfect fit and smooth operation, especially in custom or precision applications where door alignment is critical to the machine’s performance.

Compatibility with Various Door Materials and Machine Types

Not all hinges are suitable for every door material or machine type. Ensuring compatibility between the hinge and the door material, whether it’s metal, wood, or composite, is vital for both performance and durability. Similarly, the hinge design should be appropriate for the type of machine it’s being used on, taking into account factors like the door’s weight, usage frequency, and environmental conditions.

Consider consulting with hinge manufacturers or specialists to select the best type for your specific application, ensuring that the hinges will not only fit but also perform optimally.

Maintenance and Lubrication Requirements

Maintenance is a crucial aspect of keeping machine door hinges in optimal condition. Select hinges that are easy to maintain and have clear lubrication requirements to ensure smooth operation over time. Some hinges are designed with self-lubricating features or materials that reduce the need for frequent maintenance, which can be beneficial in hard-to-reach areas or in applications where minimal downtime is crucial.

Understanding the maintenance needs of your hinges can help prevent wear and tear, ensuring the longevity and reliability of your machinery’s doors.

Environmental Resistance (temperature, chemicals)

Environmental factors such as temperature extremes and chemical exposure can significantly affect hinge performance. Choosing hinges that are designed to withstand your specific environmental conditions is essential for ensuring they function correctly and last as long as possible. Materials and coatings that resist temperature changes, UV light, and chemicals can prevent degradation and failure.

When selecting hinges, consider the environmental challenges they will face and opt for products specifically rated to withstand those conditions, ensuring uninterrupted operation of your machinery.

Customization Options

In many cases, off-the-shelf hinges may not meet the unique requirements of specific machinery or applications. Customization options, including size, material, and finish, allow for a perfect match to your machine’s specifications and operational needs. Many manufacturers offer custom hinge solutions that can accommodate unusual sizes, shapes, or functions.

Discussing your specific needs with a manufacturer can lead to a custom-designed hinge that meets all your criteria, including load capacity, environmental resistance, and aesthetic considerations. For more details on ordering hinges, check out this article, How to custom a stainless steel industrial hinge?

Noise Reduction

For machines located in quiet environments or where noise reduction is critical, selecting hinges designed to minimize sound is important. Features such as nylon bushings, soft-close mechanisms, and specially designed bearings can significantly reduce the noise generated by opening and closing doors. This is particularly relevant in settings such as hospitals, offices, and residential areas, where excessive noise can be disruptive.

Choosing hinges with noise-dampening features can contribute to a more pleasant and quiet operational environment, enhancing the user experience and complying with noise regulations.

Availability of Replacement Parts and Accessories

Finally, consider the availability of replacement parts and accessories for the hinges you choose. Being able to quickly obtain replacements or specific components can be crucial in minimizing downtime and maintaining the functionality of your machinery. Opt for hinges from manufacturers with a reliable supply chain and support for their products.

Having access to a range of compatible parts and accessories allows for easier maintenance and repairs, ensuring that your machine doors continue to operate smoothly and securely over their lifespan.

Conclusion

Selecting the right machine door hinges involves considering a multitude of factors, from durability and environmental resistance to safety features and noise reduction. By taking the time to evaluate these aspects carefully, you can ensure that your machinery operates efficiently, safely, and with minimal downtime. Remember, the right hinge not only supports the door but also the overall performance and reliability of your machine. If you need customized machine door hinges, then you have come to the right place, feel free to contact IHINGES for solutions.

You might be interested:

- Top 10 Frequently Asked Questions About Offset Pivot Hinge

- 10 Common Knowledge About Heavy Duty Piano Hinges

- Top 10 Common Things to Know Before Purchasing Brass Piano Hinges