Hinges are a kind of mechanical spare parts product. Its main function is to connect the door and the door frame and has certain load-bearing properties. Different hinge structures and installation methods determine the opening angle of the door. In order to realize these functions of the hinge, there are several basic components to be considered during the design phase of the hinge.

A hinge is primarily made up of two flat components known as leaves or plates. These plates are designed to attach to the surfaces being joined, such as a door and its corresponding frame. Each leaf has cylindrical parts called knuckles, which interlock with each other. The pin, a rod-like structure, is inserted through these knuckles to hold the leaves together and facilitate the rotational movement. The leaves also feature screw holes, which are used for securing the hinge to the attached surfaces. Typically, screws or bolts are used as fasteners to accomplish this. Overall, these parts work in concert to allow for the hinge’s intended pivoting action.

There is actually more you need to know about hinges, and the following is the most comprehensive introduction to hinge knowledge. You can read on.

What are hinges?

Hinges are mechanical devices that connect two objects and allow them to rotate relative to each other. They are typically used to enable doors, gates, lids, or other objects to swing open and closed. Hinges are found in various applications, ranging from everyday household items like cabinets and refrigerators to industrial machinery and vehicles. The basic function of a hinge is to provide a pivoting point that enables two connected components to rotate freely while maintaining their relative alignment. They are usually made of metal, although plastic and other materials can also be used depending on the specific application and load-bearing requirements.

What are the two main categories of hinges?

The two main categories of hinges are commercial hinges and industrial hinges.

Commercial Hinges

Commercial hinges are generally designed for lighter-duty applications and are commonly found in residential and commercial settings like homes, offices, and retail stores. These hinges are often made of materials like brass, stainless steel, or even plastic. The emphasis is typically on aesthetics and functionality, which is why you can also find a variety of finishes such as chrome, bronze, or satin nickel to match decorative styles.

Commercial hinges are usually easier to install and may come in decorative styles given that they’re frequently visible in their applications. These types of hinges might include door hinges, cabinet hinges, and window hinges, among others. The load-bearing requirements are typically moderate, and they are designed for relatively less frequent use as compared to industrial hinges.

Industrial Hinges

On the other hand, industrial hinges are engineered for heavy-duty applications and are meant to withstand high loads and frequent usage. They are often found in factories, heavy machinery, commercial vehicles, and other settings where durability and strength are paramount. Made from robust materials like heavy-gauge steel or specialized alloys, industrial hinges are built to last and usually prioritize function over form.

Unlike commercial hinges, they often require specialized installation, given their significant load-bearing capacity. Types of industrial hinges may include heavy-duty gate hinges, machine hinges, and specialized hinges for use in extreme environmental conditions. These are built for endurance and often undergo rigorous testing to ensure they meet specific industry standards.

Leaf of hinges

The leaf of a hinge is one of its most critical components, often made of metal but sometimes of other materials like plastic, depending on the application. Essentially, the leaf is a flat or slightly curved plate that attaches to the object that needs to pivot, such as a door or a gate. Each hinge typically has two leaves, which are aligned and connected to enable the rotational movement around a common axis.

The leaves have holes, known as screw holes, through which screws or bolts are inserted to affix the hinge to the respective surfaces—be it wood, metal, or some other material. In some designs, the leaves might have notches or recesses to facilitate a more secure fit, providing better load distribution and reducing the stress on individual screws.

In terms of function, the leaf works in concert with other components, such as the pin and knuckles, to allow for smooth movement. The knuckles of each leaf interlock with those of the opposite leaf, and the pin is inserted through these interlocking knuckles to hold the assembly together. When the leaves are properly aligned and secured, the hinge can operate smoothly, transferring the rotational forces efficiently while allowing for precise control of the movement.

The design and thickness of the leaf often vary depending on the application. For example, a door hinge in a residential setting may have a comparatively thin and decorative leaf, whereas an industrial hinge designed for heavy machinery would require a robust, thick leaf capable of withstanding significant mechanical stress. Overall, the leaf is an indispensable part of the hinge, providing both the structural framework and the functional capability for rotation.

Knuckles of hinges

The knuckles of a hinge play a vital role in its function. They are the cylindrical parts that protrude from the leaf of the hinge. Each leaf has its own set of knuckles, which align and interlock with the knuckles on the opposite leaf.

The main job of the knuckles is to hold the pin in place. The pin goes through the knuckles, allowing the hinge to pivot. In this way, the knuckles enable the rotational movement of the hinge, linking the two leaves securely while also allowing them to move relative to each other.

The design of the knuckles can vary depending on the hinge’s application. In heavy-duty industrial hinges, the knuckles may be thicker and made of stronger materials to withstand high stress. In lighter, commercial hinges, the knuckles may be smaller and less robust. Regardless of their size or material, the knuckles work in tandem with the leaves and the pin to ensure the hinge operates smoothly and efficiently.

Pins of hinges

The pin of a hinge serves as the central axis around which the hinge rotates. It is a straight rod that slides through the aligned knuckles of both hinge leaves. The pin holds the leaves together and enables them to pivot smoothly.

Material choice for the pin can vary based on the hinge’s application. In many household hinges, the pin is often made of the same material as the leaves, such as steel or brass. In industrial settings, the pin might be made of a stronger alloy to withstand heavy loads. Some pins even have a special coating to reduce friction and improve durability.

Securing the pin is crucial for hinge stability. In some designs, the pin simply slides into place and gravity keeps it there. In other types, a small clip or a set screw locks the pin to prevent it from sliding out. This ensures that the hinge remains functional and safe over time.

Introduction to different structures of hinges

Symmetrical structure:

This type of structure means that the left and right blades of the hinge are symmetrical. This is also the most common type of structure. This structure is aesthetically pleasing and commonly used. Both commercial and industrial hinges are very widely used.

They are also more economical and efficient in production. Because of the symmetrical structure of the left and right sides, only one side of the blade needs to be produced in the actual production process. When assembled, the two blades are mounted opposite each other.

Asymmetric structures:

As the name suggests, this type of structure means that the hinged blades on the left and right sides are asymmetrical. It is usually narrower on one side and wider on the other. This phenomenon is more common in industrial hinges.

If you are a sheet metal case manufacturer, then you should be aware of the dimensions of the door and frame. Usually the door frame is narrower. And door panels are wider. So when installing hinges, in order to conform to such dimensions. Then the hinges will be designed to be narrow on one side and wide on the other.

This practice makes the hinges fit perfectly with the unit and is aesthetically pleasing.

Planar structures:

Planar structure mainly means that when installing the hinge, the two blade mounting surfaces of the hinge are on the same horizontal plane. This means that the door panel and the door frame are flush. This is also a common structure. It is common for sheet metal boxes where the door is light and small. If the door of the equipment is heavier, it may not be suitable for this flat-mounted structure.

Hinges for flat structures also include symmetrical and asymmetrical structures.

Step structures:

Hinges for step construction are just the opposite of hinges for flat construction. It is where the door will protrude from the door frame installation. This is usually the case when the door is heavy and thick. Some of the customers we serve are in the industrial oven business. Doors for such equipment usually have special features. For example, to install observation windows, insulation, and so on.

In this case, it is necessary to install hinges with steps, IHINGES has produced a series of hinges for this type of structure. You can contact us for detailed specifications.

Other structures:

Other constructions are mainly hinges that are specially customized for customers. They are used exclusively for the customer’s equipment. This type of hinge is too diverse to list. Customized industrial hinges are the strength of IHINGES, so if you are looking for a manufacturer of customized hinges, you have come to the right place. Contact us now to get a proposal and a quote.

Introduction to hinges made of different materials

Cold Rolled Sheet Hinges

Advantages:

- Affordable: Cold rolled sheet metal is generally less expensive than other materials, making it cost-effective for large-scale applications.

- Ease of Fabrication: It is easier to work with and can be easily shaped or bent.

- Good Strength: Offers reasonable tensile strength, suitable for many commercial and some industrial applications.

Disadvantages:

- Corrosion: This material is susceptible to rust and corrosion if not properly coated or maintained.

- Less Aesthetic: Typically lacks the polished appearance that materials like stainless steel offer.

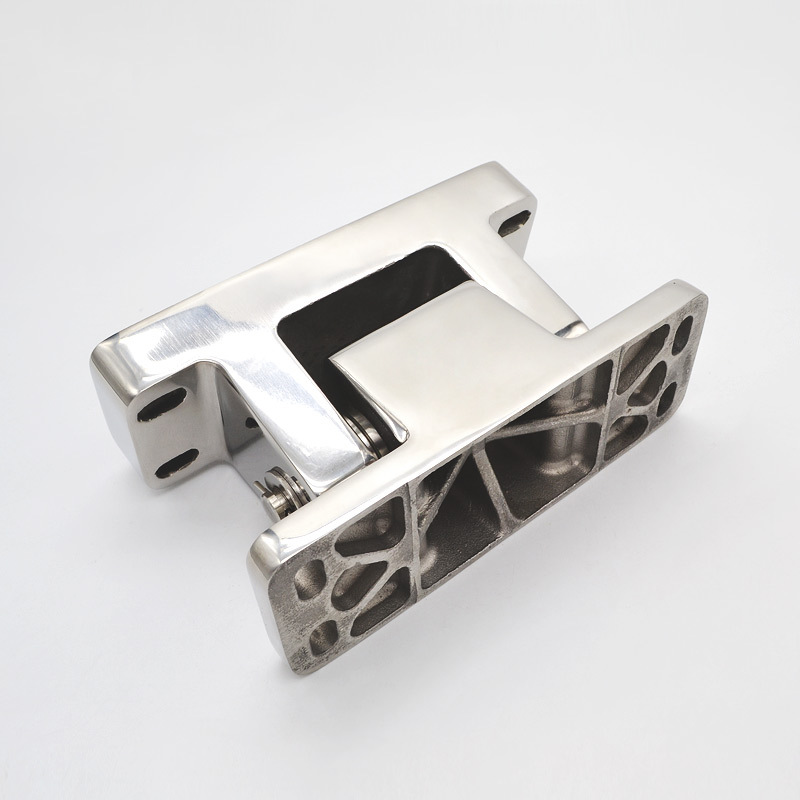

304 Stainless Steel Hinges

Advantages:

- Corrosion-Resistant: Highly resistant to corrosion, making it ideal for outdoor or harsh environments.

- Durability: Offers excellent durability and can withstand heavy loads.

- Aesthetic Appeal: A polished look is more visually pleasing than other materials.

Disadvantages:

- Cost: Generally more expensive than other materials.

- Weight: Tends to be heavier, which might not be ideal for all applications.

Zinc Alloy Hinges

Advantages:

- Lightweight: Lighter than steel, making it easier to handle and install.

- Corrosion Resistance: Often coated for added resistance to corrosion.

- Economical: More cost-effective than stainless steel but offers some of its benefits.

Disadvantages:

- Strength: Generally not as strong as steel, making it unsuitable for heavy-duty applications.

- Brittleness: Can be more brittle compared to other metals, making it less durable in certain settings.

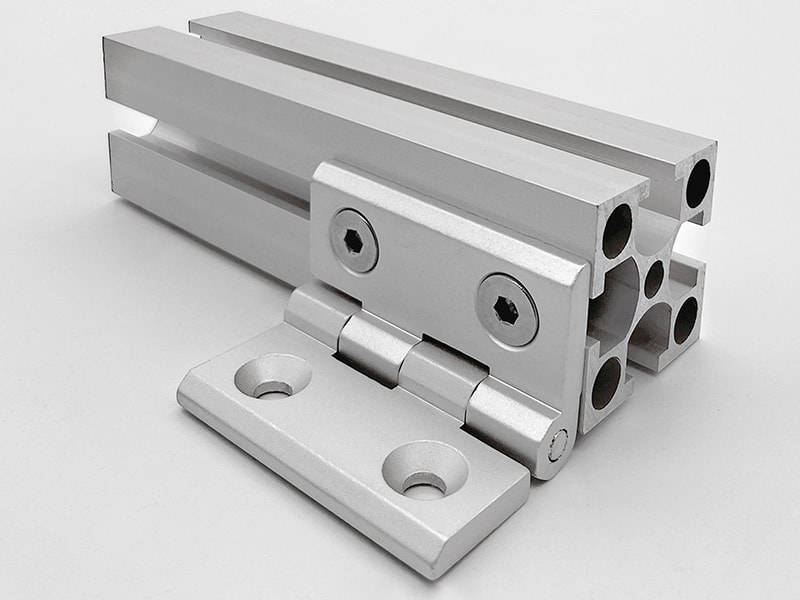

Aluminum Hinges

Advantages:

- Lightweight: Extremely light, making it ideal for applications where weight is a concern.

- Corrosion-Resistant: Naturally forms a protective oxide layer, making it resistant to corrosion.

- Malleability: Easy to shape and machine, offering design flexibility.

Disadvantages:

- Strength: Not as strong as steel, so not ideal for heavy-duty applications.

- Cost: Can be more expensive than other lightweight materials like zinc alloy.

Nylon Hinges

Advantages:

- Lightweight: Extremely light and ideal for applications where weight is crucial.

- Corrosion-Resistant: Resistant to rust and many chemicals.

- Low Friction: Natural lubricity makes for smooth operation without the need for additional lubricants.

Disadvantages:

- Strength: Generally the least strong among these options, unsuitable for heavy-duty or high-stress applications.

- Temperature Sensitivity: Can be less stable under high temperatures, potentially leading to warping or melting.

Introduction to special purpose hinges

Special purpose hinges are very diverse. Often they need to be customized. This is because we cannot know what kind of equipment the customer will design. The function and structure of the hinge need to be customized according to the customer’s equipment.

IHINGES has designed and produced a large number of customized hinges for our customers. We have accumulated a lot of experience. The fields that have been involved are medical, industrial ovens, rail transportation, and agricultural machinery.

How to choose the right hinge?

Choosing the right hinge starts with understanding your specific needs. First, identify the weight and size of the door or object you’re attaching. Heavier doors need stronger materials like stainless steel. Lighter doors can use aluminum or even nylon hinges. Next, consider the environment. If the hinge is for outdoor use, go for corrosion-resistant materials like stainless steel or aluminum.

Functionality is another factor. Decide if you need the hinge to lock, swing in multiple directions, or self-close. Then, think about aesthetics. Choose a finish or material that complements your overall design. Keep in mind that some materials are more decorative but less strong, like zinc alloy.

Installation ease is also crucial. Check if the hinge style allows for easy installation or if you need professional help. Lastly, budget matters. While stainless steel is strong and durable, it’s also more expensive. Weigh your needs against your budget to make the final decision.

How to purchase hinges in bulk?

If you purchase hinges in bulk from us IHINGES. You only need to provide the specific requirements of the hinges. Do you need to order new hinges for your equipment or do you want to use existing hinges from our stock?

We will reply to you with the specific product price and delivery time, including any other ordering requirements you may have. For customized hinges, the lead time will be longer. Before mass production, we will provide samples for trial fitting. We will make mass production only after the sample is confirmed.

For more specific details of bulk purchases, please contact us.

Conclusions:

Above is a comprehensive introduction to hinges, hope it can help you.IHINGES is a professional manufacturer of industrial hinges. If you need customized hinges, you can contact us now to get a proposal and quotation.

You might also be interested: